Yes, hot water is nice, but not when it comes out of the cold tap in the darkroom. Guess since the beginning of photography all wet processes are assumed to be run at 68F. Personally I have nearly always ran everything at 70F. This seems to be a good compromise since we live in Texas, where in a 12 month year, summer is 18 months long. Personally, I don’t care for temperatures to be much above 70F outside, but what can you do?

Yes, hot water is nice, but not when it comes out of the cold tap in the darkroom. Guess since the beginning of photography all wet processes are assumed to be run at 68F. Personally I have nearly always ran everything at 70F. This seems to be a good compromise since we live in Texas, where in a 12 month year, summer is 18 months long. Personally, I don’t care for temperatures to be much above 70F outside, but what can you do?

The cold tap here runs up near 88F by August, and for many years I dealt with that by freezing plastic bottles filled with water. Works well enough, but is still a hassle. Finally about 18 years ago I decided to look into a water chiller for the darkroom. I have to admit that I did try the coil of copper tubing in a washtub of ice water. Works to some degree, but is a mess to deal with. What I wanted was a no-muss, no-fuss way to chill the water to a manageable temperature.

So, you say you want a water chiller? That really is not a problem. There are commercial units that will provide very high volumes of chilled water. Problem is, they are large and expensive. So, like most things I had to find a balance between useable and practical. Everything is a tradeoff of some sort. I did a lot of research and eventually decided, based upon the limiting factors I had to face, that a small ElKay remote water chiller would be satisfactory. The unit I settled on was their Model ER101Y, which is rated as a 9.6 GPH (Gallon Per Hour) remote chiller. The unit was small enough to fit under the darkroom sink and ran off a 115 volt circuit.

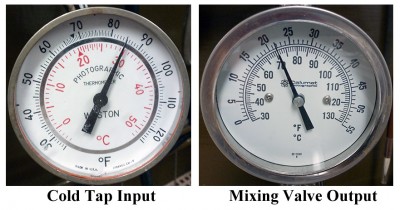

Now, the bottom line is, how well does this work? I have to admit it is not perfect, but it is certainly better than nothing and much better than anything else I had tried. The setup is very simple. I have a Calumet/Lawler mixing valve that in winter, when the cold tap is in the 50-60F range works very well. By adding the chiller in the summer I can keep a steady 70-72F wash water with cold tap up toward 85F, with a flow rate of about 0.75 GPM for as long as I need. This is plenty good enough for washing film or paper. We mostly process paper in the summer anyway, and when the tap gets to 88F the wash water goes to about 75F.

Not everything is perfect though. I would really like to run any flow rate for any length of time, at any reasonable cold tap temperature, but it will not happen with this small of a chiller. That would require more horsepower. Another thing to think about is the heat generated by the chiller. I had to add a powered wall vent next to the chiller to keep the room from heating up. The ultimate would be to vent the unit outside, but that isn’t practical for my location. . . so I just have to deal with it as best I can.

At least I do have a chiller and it does work. When I get ready to process film or print, I will fire up the chiller and allow it to cycle. This normally takes about fifteen minutes. I can then fill my washers, but I have to watch the temperature closely, because at full flow the chiller will run out of cold water pretty fast. When I see the mixing valve temperature start to rise, I will shut off the water and wait for the unit to cycle again.

Bottom line is, I would not want to be without my chiller. If I had the choice, I would upgrade to the larger ElKay ER191, which is a 19GPH unit. It would fit in the space now available. The original sink I installed the unit we have on did not have room. If I were going to suggest a chiller, I would say get the 19GPH unit. But do keep in mind that any chiller is better than none!

JB