If you build you own darkroom sink or use a commercially available unit, you need something to protect the floor of the sink from scratches and abrasions. It has been a common practice to construct wooden Duck Boards for the bottom of the darkroom sink. These work well, they protect the sink, and allow water to drain, but wood is hard to waterproof and keep from warping.

If you build you own darkroom sink or use a commercially available unit, you need something to protect the floor of the sink from scratches and abrasions. It has been a common practice to construct wooden Duck Boards for the bottom of the darkroom sink. These work well, they protect the sink, and allow water to drain, but wood is hard to waterproof and keep from warping.

I have heard of people using plastic lighting grids or plastic rods in the sink, but I have never tired them. I have constructed and used the usual wooden Duck Boards for years. Then I found something even better.

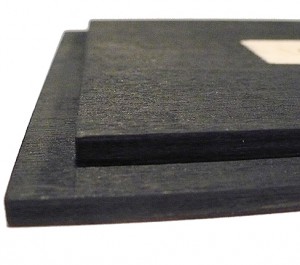

Dri-Dek® is sold as an anti-fatigue flooring for use in commercial work areas such as industrial manufacturing or commercial kitchens. It comes in 12” interlocking squares or rolls. This is a soft, flexible Vinyl that is perfect for the floor of a darkroom sink.

We installed Dri-Dek® in our sink two years ago and it has been an excellent investment. Water easily runs through and under the lattice work, it protects the sink floor, and it provides a soft, yet firm surface on which to work. Note, that the Vinyl does stain when exposed to some chemicals, like Amidol and Pyro, but it has remained flexible and I would not hesitate to recommend it to replace those old, warped wooden Duck Boards.

For more information about Dri-Dek® click HERE.

JB

Once you become a serious darkroom worker you will eventually want a real darkroom sink with running water. The question is, to buy, or to build? Certainly, if you have deep pockets, you can buy a commercial stainless steel sink. You can even have a stainless sink custom fabricated. Just be forewarned, you are looking at a serious amount of money.

Once you become a serious darkroom worker you will eventually want a real darkroom sink with running water. The question is, to buy, or to build? Certainly, if you have deep pockets, you can buy a commercial stainless steel sink. You can even have a stainless sink custom fabricated. Just be forewarned, you are looking at a serious amount of money.

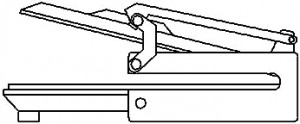

How do you identify sheet film? You put unique numbers on the film holder, but how can you identify which sheet of film came from any particular holder? You may be able to identify the film by taking notes and knowing the subject. But, what if you make several exposures of the same scene, say using different filters? How do you know which filter was used on each sheet?

How do you identify sheet film? You put unique numbers on the film holder, but how can you identify which sheet of film came from any particular holder? You may be able to identify the film by taking notes and knowing the subject. But, what if you make several exposures of the same scene, say using different filters? How do you know which filter was used on each sheet?