CONSTRUCTION OF THE 4X10 VERTICAL CAMERA

GETTING STARTED

The project begins as an idea. . .

The project begins as an idea. . .

The design is a modification of an existing camera, which is disassembled and measured. Drawings and sketches are made, then the drawings are modified for the new vertical camera final design.

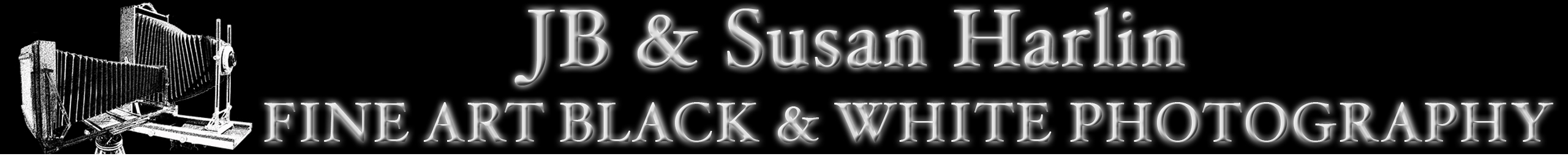

Raw, rough cut, mahogany is shaped into rough stock. . .

Raw, rough cut, mahogany is shaped into rough stock. . .

. . . then the wood is fine shaped and cut into finished wood blanks.

. . . then the wood is fine shaped and cut into finished wood blanks.

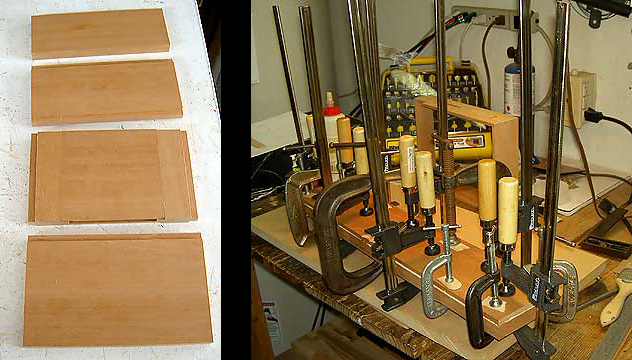

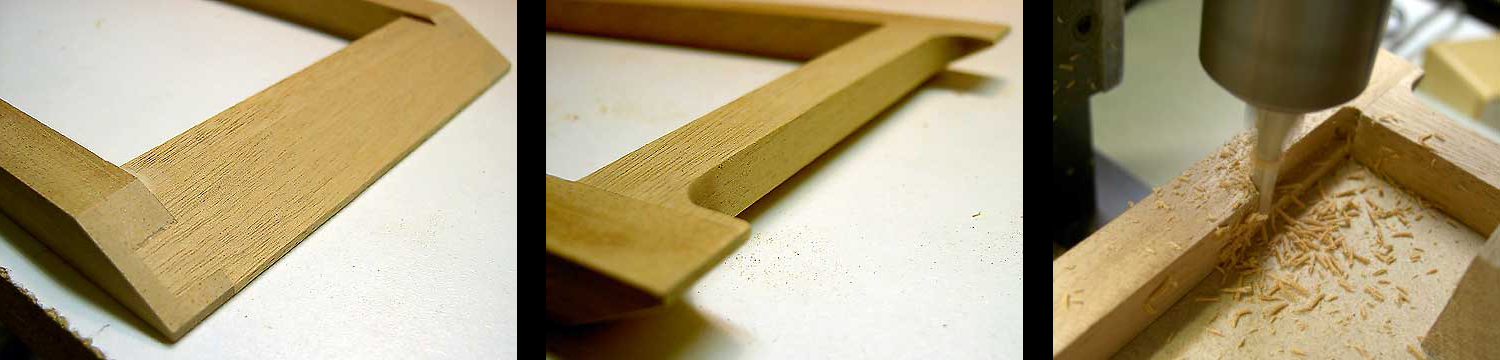

Once cut to their final size, the wood is cut with a tongue and groove bit. . .

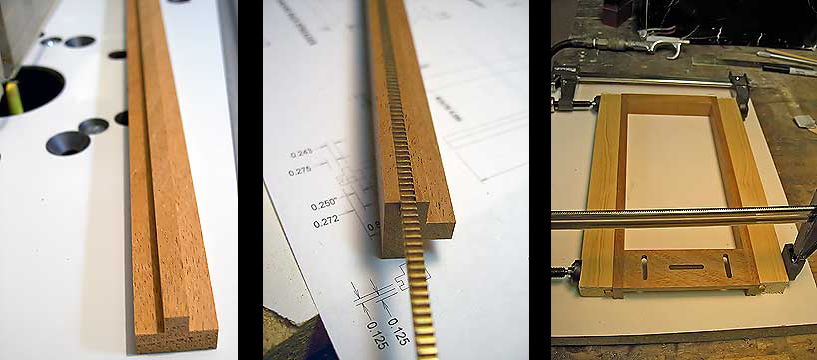

the pieces are assembled dry to check for correct fit, then glued and clamped.

the pieces are assembled dry to check for correct fit, then glued and clamped.

Once the glue is dry the outer edge is trimmed to size. . . this is the base of the camera.

Once the glue is dry the outer edge is trimmed to size. . . this is the base of the camera.

The base is next machined to accept various hardware necessary for the focus slides and drive mechanism.

The base is next machined to accept various hardware necessary for the focus slides and drive mechanism.

This is the complete base with drive hardware and focus guides installed.

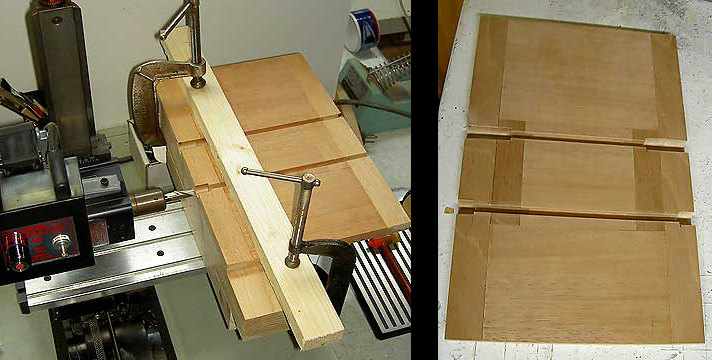

The rear box of the camera is constructed using box joints. The joints are cut using a custom box joint jig, then each piece is cut to final size and any machine work necessary is done before gluing. Note level cutout in the photo on the right.

Here is the completed rear camera box.

Here is the completed rear camera box.

Wood is cut and shaped to form the ground glass frame.

The ground glass frame is shaped and the relief is machined for the glass.

Next the main back assembly is built up from several formed pieces of raw wood, then machined to accept the ground glass back and its hardware.

Here is the complete camera back assembled.

The ground glass springs are formed from raw spring steel flat stock. After heating and forming the springs are buffed on a buffing wheel using polishing rouge.

The mating drive sliders are formed, machined to accept the rack drive gears and then attached to the cross pieces to form the front focus bed.

The rear spreader is machined and attached to the outer sliders to form the rear focus bed.

Wooden pieces are machined to form the front standard. The light trap is machined to accept the lens board. Also the front bellows frame (right photo) that attaches to the rear of the front standard with sliding hardware is constructed from raw wood.

Wooden pieces are machined to form the front standard. The light trap is machined to accept the lens board. Also the front bellows frame (right photo) that attaches to the rear of the front standard with sliding hardware is constructed from raw wood.